Pre Engineering Building

Home

/

Pre Engineering Building

Pre Engineering Building

-

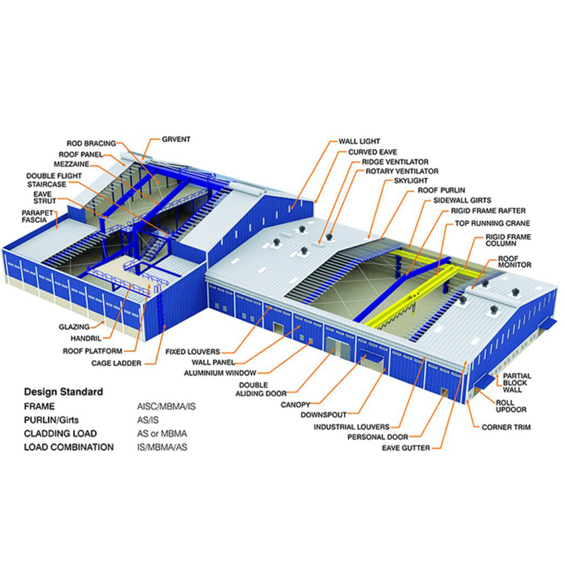

Easy integration of all traditional construction materials such as brick work, glazing, timber etc.

-

The main buildingstructure comprises single or multiple gable interior rigid frames with either rigid or "post-and-beam" frames at the end walls.

-

The standard roof slopes are 0.5 or 1.0 unit of Vertical rise to 10 units of horizontal run.Other Slopes are available upon request.

-

The sidewall steel line is the plane of the inside vertical surface of the sidewall sheeting.It is also the plane of the outside vertical surface of the eave strut.

-

The end wall steel line is the plane of the inside vertical surface of the end wall sheeting.It is also he plane of the outside vertical surface of the outer flange of the end wall garters

-

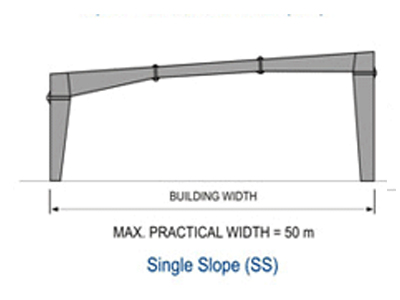

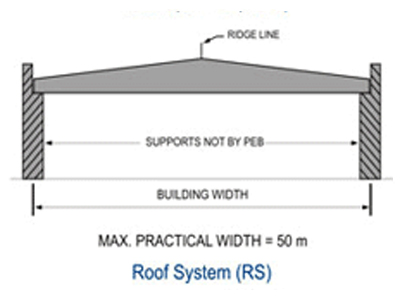

The building width is the distance between the steel lines of opposite sidewalls.Building width does not include the width of Lean-To buildings or roof extensions. The width of a Lean-To building is the distance from the steel line of the exterior sidewalls of the Lean-To building to the (sidewalls or end walls) steel line of the main building to which the Lean-To building is attached.

- The building length is the distance between the steel lines of opposite end walls.Building length is a combination of several bay lengths. Building length does not include the width of end wall Lean-To buildings or roof extensions.

- End bay length is the distance from the outside of he outer flange of end wall columns to the center line of the first interior frame.

- Interior bay length is the distance between the center lines of two adjacent interior rigid frame columns.

- The building eave height is the distance from finished floor level (FFL) to the top of the eave strut at the sidewalls steel line.

- The building clear height is the distance from finished floor level (FFL) to the bottom of the end plate of the rafter at the knee.

-

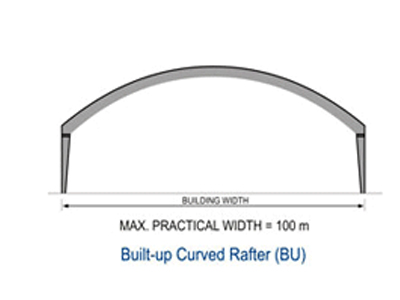

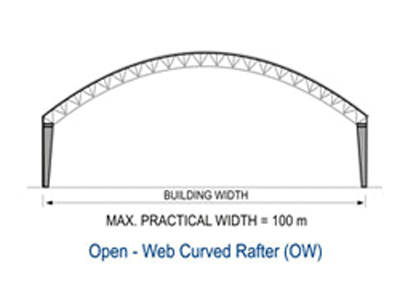

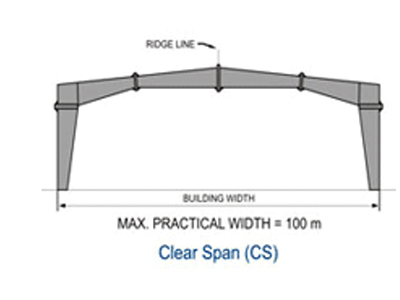

Clear Span (CS) buildings have a gable roof with vertical sidewalls and end walls. Interior bay frames are clear span rigid frames without interior columns.

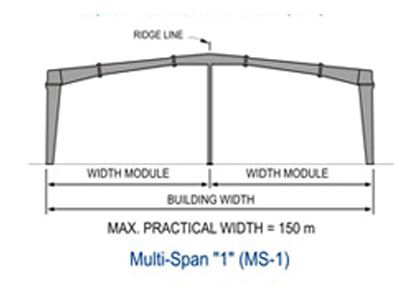

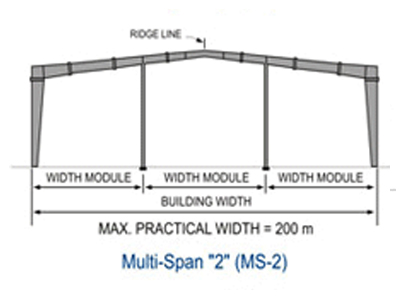

- Multi-Span (MS) buildings have a gable roof with vertical sidewalls and end walls. Interior bay frames are rigid frames, typically with tapered exterior columns, tapered rafters and square tube or build –up interior columns.

- Space Saver (SV) buildings have a gable roof with vertical sidewalls and end walls. Interior bay frames are clear span rigid frames having constant depth columns and tapered rafters typically with horizontal bottom flanges.

- Lean-To (LT) buildings consist of outer sidewall columns and simple span rafters attached to the sidewall columns or the end wall posts of the main building. Lean-To columns are of constant depth Lean-To rafters may be tapered or of constant depth.

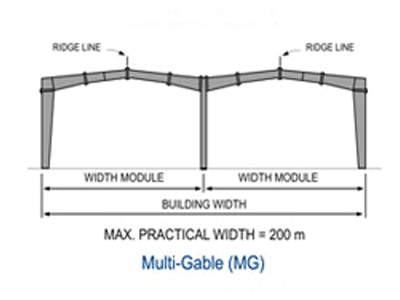

- Multi-Gable (MG) buildings have a roof with two or more gables and vertical sidewalls and end walls.Interior bay frames are rigid frames typically having tapered exterior columns, tapered rafters and built-up interior columns.

- The building clear height is the distance from finished floor level (FFL) to the bottom of the end plate of the rafter at the knee.

Standard Framing Features

-

Main frames are typically constructed from tapered or constant depth columns and rafters

-

Rigid frames for Clear Span (CS) and Multi-Span (MS) buildings are most commonly spaced from 6000 mm to 10000 mm, center line to center line.

-

Outside flanges of Clear Span (CS) and Multi-Span (MS) rigid frame columns are inset 200 mm from the sidewall steel line to allow for by-pass grits.

-

Outside flanges of Space Saver (SV) rigid frame columns shall be placed flush with the sidewalls steel line.

-

The top flanges of all rigid frame rafters are 200 mm below the bottom of the roof sheeting.

-

End frames are “post-and-beam” (P&B) load bearing frames with end wall grits flush framed into he webs of the end wall posts so that the outer flanges of the grits are in the same vertical plane as he outer flanges of the posts. Optional rigid frames may be used at the building ends.The center line of the end walls rigid frame shall be 385 mm from the end walls steel line

-

End wall posts are typically spaced at 6000 mm. Depending on the width of the building and end wall openings, other spacing may also be used When the building width is not evenly divisible by 6000 mm, the interior spacing of the end wall posts is typically kept at 6000 mm with two equal end spacing’s smaller or larger than 6000 mm.

- For Clear Span (CS) and Multi-Span (MS) buildings, the sidewall grits are attached (by-passed) to the outer flanges of exterior columns. Sidewall grits are lapped at all interior frames For Space Saver (SV) and Lean-To (LT) buildings, the sidewall grits are flush connected (flush framed) so that the outer flange of the garters is in the same vertical plane as the outer flange of the exterior columns.

- The bottom flanges of roof purlins are attached to the outer (top) flanges of the rafters. Purlins are lapped at all interior frames in all structural framing systems.

Building Components

-

Columns and rafters of rigid frames are tapered built-up “I” sections. Interior columns of multi-span frames may be square tube sections.

-

All rigid frame connections are bolted. Columns and rafters are provided with welded end plates for anchoring to foundations and for member-to- member attachment. Pre-punched holes or welded clips are provided for attachment of purlins and girters, bracing, and other components.

-

Load bearing “post-and-beam” (P&B) end frames may be constructed from cold-formed channels,hot rolled sections or built-up welded plate sections,as required.

-

Purlins and girts are pre-punched cold-formed “Z” shaped sections,200 mm in depth with stiffened flanges.

-

Eave struts are pre-punched cold-formed “C” shaped sections,180mm in depth with 85mm shaped sections,180 mm in depth with 85mm longitudinal structural bracing member in addition to acting as a transition point for walls and roof sheeting.

-

Panels(roof and walls) are roll formed to the maximum practical length (generally 9000 mm) to minimize end laps in the field.

-

The standard roof and walls panel is Profile “S” It is a roll formed panel having 4 major high ribs and 4 minor ribs.The panel covers a width of 1000mm.The lapped major rib has a siphon break to prevent capillaric intrusion of water at the side lap. The panel has an extended bearing leg to provide stiffening during installation.

- Roof panels have a minimum end lap of 150mm over purlins and are fully protected from siphon action by an end lap mastic.

- Wall panels have the same side lapping as the roof panels. End lap is 100mm over the girts Generally no side or end lap mastic is required.